POWDER COATING

October 2014 saw the installation and commissioning of our new Wagner PrimaSprint Plastic Cabin Powder Spray Booth complete with ProfiTech Sprint control system with a 3 stage iron phosphate pre-treatment plant, dry-off and main cure ovens. This is the most advanced plant available, which, as well as offering a higher quality finish, allows us to reduce our lead times even further in addition to having complete control of our manufacturing process from initial enquiry to final delivery.

We are also, for the first time, able to offer sub-contracting coating services. Please contact our sales team for further information.

WHAT IS POWDER COATING

Powder coating is a very similar process to painting except that the “paint” is a dry powder rather than a liquid. The powder sticks to the parts due to electrostatic charging of the powder and grounding of the parts.

THE POWDER COATING PROCESS

The component to be coated is first cleaned with a combination of degreaser & iron phosphate to remove any surface grease or metal fragments & provide an anti corrosion substrate. It is then…

…thoroughly rinsed first with hot water & then with cold to remove all traces of chemical before being…

… dried in preparation for coating.

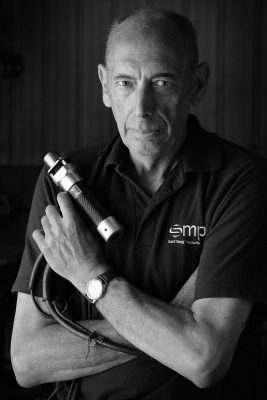

The power coating is then applied by power-gun either automatically or, if the part is a more complex shape by hand, to ensure all surfaces are evenly coated.

A “baking” or curing process is then undergone to dry and harden the coating to a solid finish. The part is now ready for packing /assembly.